Authors: F. Drouet, P. Croüail (CEPN, France)

Introduction

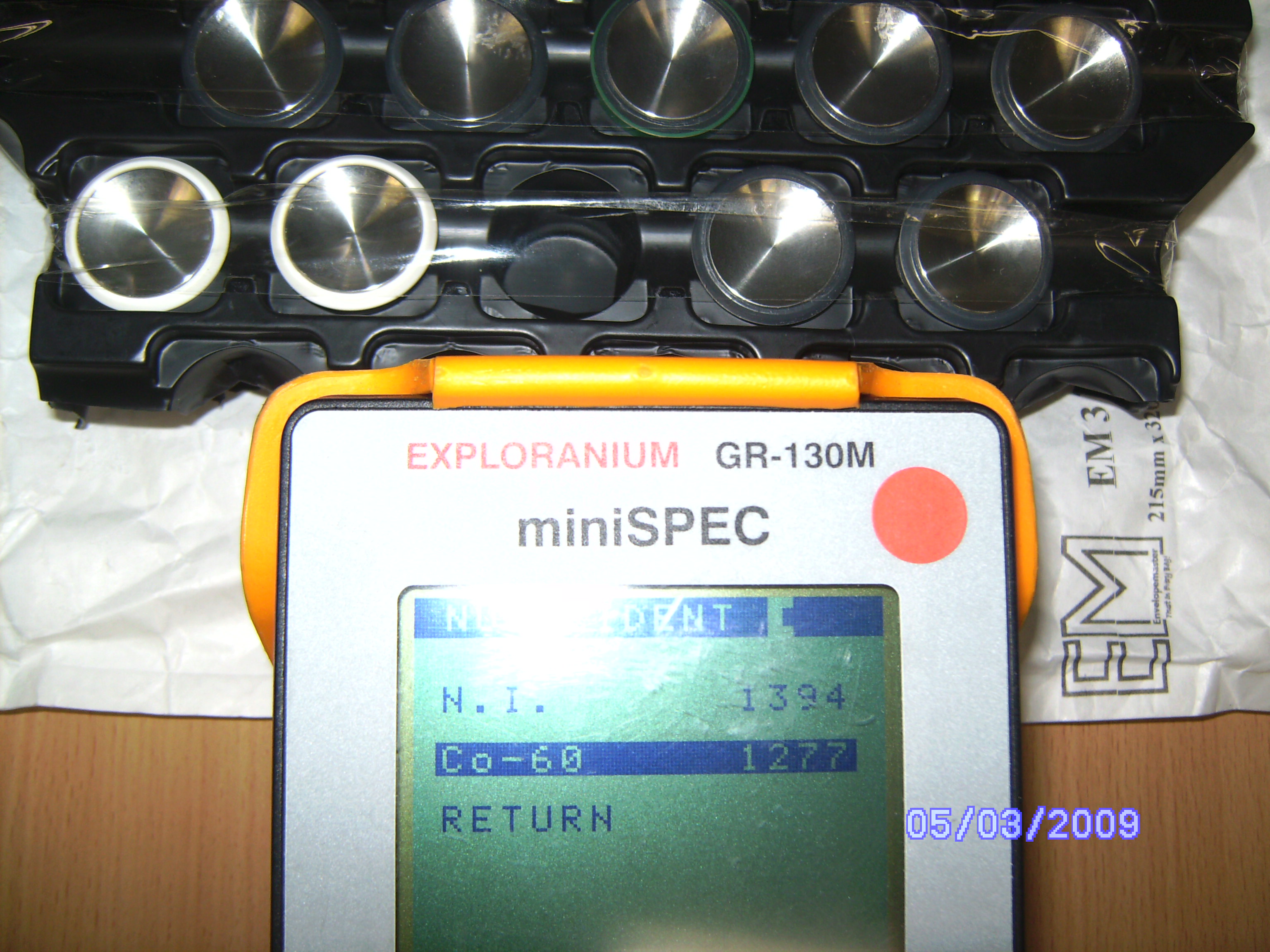

In October 2008, the French nuclear safety authority (ASN) was informed about the detection of radioactivity in lift buttons, manufactured by a French company, MAFELEC. This company manufactures lift buttons whose metal base comes from India. The detection was made on the assembled buttons and it appeared that the 60Co contamination came from Indian suppliers. After investigation by the French authority, it turned out that MAFELEC has only one customer, OTIS, a lift company located in several places all over the world. As a consequence the distribution of contaminated buttons was not limited to France and measures to identify and remove buttons were taken in many countries in Europe.

In October 2008, the French nuclear safety authority (ASN) was informed about the detection of radioactivity in lift buttons, manufactured by a French company, MAFELEC. This company manufactures lift buttons whose metal base comes from India. The detection was made on the assembled buttons and it appeared that the 60Co contamination came from Indian suppliers. After investigation by the French authority, it turned out that MAFELEC has only one customer, OTIS, a lift company located in several places all over the world. As a consequence the distribution of contaminated buttons was not limited to France and measures to identify and remove buttons were taken in many countries in Europe.

At the occasion of the EAN Steering Group meeting in December 2008, discussions confirmed that many EAN countries had to deal with this issue. Then EAN decided to launch a request through its mailing list for information on the management of this event in European countries. Between January and July 2009, answers from 13 different countries were received. This article is a summary of these answers.

The management of the contamination in France

After being informed and after an inspection of the MAFELEC site, the French nuclear safety authority asked the technical support of the Institute of radiation protection and nuclear safety (IRSN) to assess doses and dose rates for company workers and the public.

The measurements performed by IRSN revealed ambient dose rates between 1 and 20 μSv/h at the workplace at the MAFELEC site. A first dose assessment performed at the end of October 2008, based on conservative hypothesis, indicated that 22 persons might have received more than 1 mSv (up to 2.7 mSv) between August and October 2008. After receiving more detailed information from the company about the real exposure time of the workers, a new assessment was performed leading to a maximum estimated individual dose of 0.5 mSv. IRSN also performed an evaluation of the maximum dose that could be received by an individual due to exposure to the buttons in a lift. The results showed that the dose could not exceed 0.15 mSv for a person of the public.

At the request of MAFELEC senior management, IRSN also organized a meeting to inform workers about the risks associated with ionizing radiations. Moreover, the following actions were agreed with OTIS:

- Radiation measurements on OTIS sites in France,

- Actions to remove contaminated buttons from the lifts (undertaken by OTIS staff),

- Education and training of persons in charge of removing the buttons,

- Information to employees about exposures and risks.

In total, a few hundreds lifts were checked for contamination. The contaminated buttons are now considered as radioactive waste and will be managed in France accordingly. ASN classified this event at level 2 on the INES scale. This event had an important media impact in France with the dissemination of information on TV and in newspapers. Information on the evolution of the situation was mainly disseminated through ASN and IRSN websites.

The management in European countries

The buttons containing contaminated metal, produced in France by MAFELEC, were devoted to the international market. Thus the installation of contaminated buttons in lifts within Europe was highly probable. That is why, in many countries, campaigns to identify and remove potentially radioactive buttons were organized by OTIS with the support of the national safety authorities. Information of this event was spread out through different channel: exchanges between nuclear safety authorities, between OTIS national roots, information through ECURIE system. Even exchanges within EAN favour diffusion of information.

The extent of the potential contaminated buttons differed from country to country. In Greece, OTIS asked the Greek authority to do measurements in 3 newly installed lifts. No contamination was found. In Slovenia, only few lifts were concerned and no contamination was found as well. In contrast, in Germany, the technical expert TÜV measured more than 6000 buttons, 60 of which were contaminated. Removal of all contaminated buttons was performed by OTIS, with the advisory support of TÜV. In the Czech Republic, measurements performed at OTIS facilities revealed that, among 1050 buttons, more than 80% (859) were contaminated (maximum dose rate: 70 μGy/hr; total estimated activity: 43 MBq of 60Co). However, these buttons were not installed yet and were stored in a room with low occupational factor: there was then no risk for the public and the risk for workers was minimal. Measurements were also performed in installed lifts all over the country, which resulted in OTIS staff removing 75 contaminated buttons.

Beyond the identification and removal of contaminated buttons, authorities in some countries performed more detailed radiation protection studies to assess the level of contamination and the consequences on workers, who were in charge of installing the lifts, and on the public.

In the UK, MAFELEC informed OTIS about the possible contamination. OTIS then contacted HPA for assistance. HPA performed measurements at the companys main site and in a selection of potentially affected lifts. Dose rates up to 25 μSv/h at the surface of the button and less than 1 μSv/h at 30 cm were measured. Activity measurements were performed on two buttons: the maximum activity was estimated to be 4 kBq of 60Co (equivalent to about 200 Bq/g). OTIS staff members were trained by HPA to monitor and to remove contaminated buttons, which were then stored at companys facilities. A simple risk assessment indicated that the risk to workers and public was minimal. In total, 150 lifts were checked and 270 buttons were identified as contaminated. Most of the contaminated buttons were located on construction sites, where the public does not have access.

In Switzerland, following articles published in the French papers, the National Emergency Operation Centre informed SUVA (Swiss national accident insurance fund) about the possible contamination of lift buttons. OTIS Switzerland was already informed by OTIS France. The companys employees were trained by SUVA to perform measurements, using borrowed radiation protection devices, and to remove contaminated material. The company checked all potential contaminated lifts and removed the contaminated buttons: 261 lifts were checked in Switzerland containing 2918 buttons, 99 of which were contaminated. The maximum dose rate at the surface of buttons was 0.6 μSv/h. The dose to workers was evaluated to less than 10 μSv. Finally the buttons were sent back to OTIS France. In terms of information, the Swiss authority did not receive any request from the public. Only short articles about the problem in France were published.

The Belgian nuclear safety authority (FANC) was informed by ASN on October 21st, 2008. OTIS France indicated that 2 lots of buttons sent to OTIS Benelux were potentially contaminated. FANC worked then with OTIS Benelux to organize measurement and to remove of all contaminated buttons. Lifts were classified in 3 categories with decreasing priority for measurements:

1) Lifts already installed and accessible for public: for this category, the measurements were performed immediately; 12 lifts were concerned and no contaminated buttons were found.

2) Lifts partly installed or in building where civil works were still ongoing (i.e. no access for the public): 58 lifts were checked; only one contained contaminated buttons (dose rate up to 4.5 μSv/hr). The contaminated buttons were removed.

3) Lift not installed: in this last category, no contamination was identified.

In total, 92 lifts and more than 450 buttons were measured; only one button was found to be contaminated. The public was informed about the contamination through FANC website.

Ireland was notified at the end of 2008 through the ECURIE System and the IAEA Illicit Trafficking Database (ITDB) programme that cobalt-60 had been detected in some elevator buttons stored in a warehouse in Italy. It was reported through EAN that these contaminated elevator buttons were also detected in the UK, which identified a sister company in Ireland (OTIS Ltd) possibly having being supplied with similar material. The RPII followed up on this and subsequently in January 2009, OTIS Ltd in Ireland contracted the RPII to survey lifts with OTIS Ltd personnel at 24 sites throughout the country.

Investigations by the RPII on behalf of OTIS Ltd identified 3 sites where contaminated or defective buttons were detected. A defective button (typically 3 cm diameter, 2 cm depth and 22.5 g in weight) was taken to be any button with a radiation dose rate in excess of natural background radiation of 0.15 μSv/h at the surface. The presence of cobalt-60 was confirmed in 28 buttons with individual surface doses rates between 0.3 - 30 μSv/h. Two of the buttons identified recorded the maximum surface dose rate of 30 μSv/h. Defective buttons were removed by OTIS Ltd personnel and then stored at the Companys facilities. It was determined that the levels of contamination were low and posed no risk to employees or members of the public. The buttons were returned in July 2009 to OTIS Ltd (UK) with the authorisation of the UK Environment Agency, for repatriation with the other contaminated buttons detected throughout the UK.

Import/export of contaminated metal: a current issue

The contaminated lift buttons is only one example of the issue of import/export of contaminated metal. Already in 2008, an article of the ALARA Newsletter described an incident involving contaminated imported stainless steel sheets in Italy (Lt. Col. R. Masi, Incident involving stainless steel sheets contaminated with Co-60 in Italy, Newsletter 23, September 2008). Moreover, a couple of weeks before the lift buttons were discovered in France, some contaminated metal flanges coming from India were discovered at a company in Sweden. This international company got first an alarm from Singapore airport and a few days later from the customs in Rotterdam. The company arranged screening for contaminated goods in Sweden, and in parallel the authority arranged contacts with radiation protection experts to perform measurements and inform the companys staff. Detailed measurement performed on one flange showed dose rate of 4-5 μSv/hr in contact. The 8 contaminated flanges were sent back to India. Some other contaminated steel issues emerged also in the UK, in Germany and Lithuania over the recent years.

In February 2009, the Spanish Nuclear Safety Authority (CSN) organized in cooperation with IAEA a conference on Control and Management of Inadvertent Radioactive Material in Scrap Metal to exchange international experience on that issue, to promote good practices to prevent inadvertent diversion of radioactive material and to identify needs for recommendations and guidance. The presentations and discussions showed that the problem is truly global in nature. In particular several examples of trans-border shipments associated with radioactive material found in scrap metal were presented. The fact is that there are no international legal instruments that cover this type of problem. As a conclusion, the need of establishing some form of binding international agreement between governments to unify the approach to trans-boarder shipments was unanimously identified.

At the European level, on 15th April 2009, the European High Level Group on Nuclear Safety and Waste Management (ENSREG) meeting raised the issue of contaminated steel products into the European Union. It decided to organise a second meeting to discuss the need for setting common actions to deal with this issue within the European Union. To prepare this meeting, the European Commission is collecting all input and ideas for a Community framework or legislative initiatives in this area.

Conclusions

Even if, finally, the radiological consequences for workers and the public were globally low, this event raises the problem of control of import/export products. The international market and the differences in the control of sources between countries make the global distribution of contaminated products possible, and make tracing this contamination quite difficult. As a consequence, in most cases the countries using final products must ultimately deal with the problem both in terms of waste management and of economical costs.

Finally, the success of this request proves the interest of EAN participants for exchanging information on radiation protection events and that the network may also sometimes be a mean for spreading event information within Europe.

We also would like to thank the persons, who participated to the survey.

A. Avetisyan (ANRA, Armenia), S. Coenen (FANC, Belgium), J. Duffy (RPII, Ireland) B. Ekström (SSM, Sweden), M. Hammans (SUVA, Switzerland), V. Kamenopoulou (GAEC, Greece), J. Kropàček (SUJB, Czech Republic) S. Risica (ISS, Italy), A. Schmitt-Hannig (BfS, Germany) P. Shaw (HPA, UK), J. Ziliukas (RSC, Lithuania), D. Zontar (SRPA, Slovenia). Moreover information from France were taken from ASN information (www.asn.fr) and IRSN reports, available in French on the Institutes website (www.irsn.fr).

Pictures were provided by the Radiological Protection Institute of Ireland (RPII)